Our approaches to the environment

The tools that create a future you desire

must not be harmful to this future.

Our products are designed to inspire the future through creative expression.

That is why we believe our products and corporate activities must not place a burden on that future.

Without a rich natural environment, there is no rich expression.

We are committed to pursuing a balance between environmental conservation and corporate activities

as an "Expression Innovation Company" that will foster the cultures of tomorrow.

Our Mission

Mitsubishi Pencil Group will work to reduce the environmental impact of its business activities throughout the entire supply chain.

We will comply with relevant environmental laws and regulations, respond to social demands, and continuously improve our implementation system and operation methods.

Mitsubishi Pencil's Key Environmental Challenges

Climate change

As the advancement of global warming continues, combating climate change has become a significant global challenge for societies at large.

The Paris Agreement adopted in 2015 also strongly calls for efforts to reduce greenhouse gas emissions.

We will forge a path to mitigate climate change by promoting the efficient use of energy and vastly reducing carbon dioxide (CO2) emissions.

We will implement activities and disclose information in accordance with the TCFD recommendations.

Information disclosure based on

the TCFD recommendations

Targets for 2030 and 2050

| 2030 | 2050 | |

|---|---|---|

| CO2 emissions | 50%reduction | 100%reduction |

| Efficient use of energy | 15%reduction | 35%reduction |

| Renewable energy | 50% | 100% |

- 2030

- 2050

- CO2 emissions

- 50%reduction

- 100%reduction

- Efficient use of energy

- 15%reduction

- 35%reduction

- Renewable energy

- 50%

- 100%

We are aiming to achieve a 50% reduction in CO2 emissions from the Mitsubishi

Pencil Group as a whole by 2030 (*1) and a 100% reduction by 2050. To this end, we are also aiming to

reduce our energy consumption by 15% (*2) by 2030 and by 35% (*2) by 2050.

In addition, we are aiming to secure 50% of our Group's total energy from renewable energy sources by 2030

and 100% by 2050.

To meet these demands for total carbon emissions reduction, it is imperative for us to also set up a

sustainable supply chain management.

- *1: Based on CO2 emissions in 2021.

- *2: Based on energy consumption (per unit of sales) in 2021.

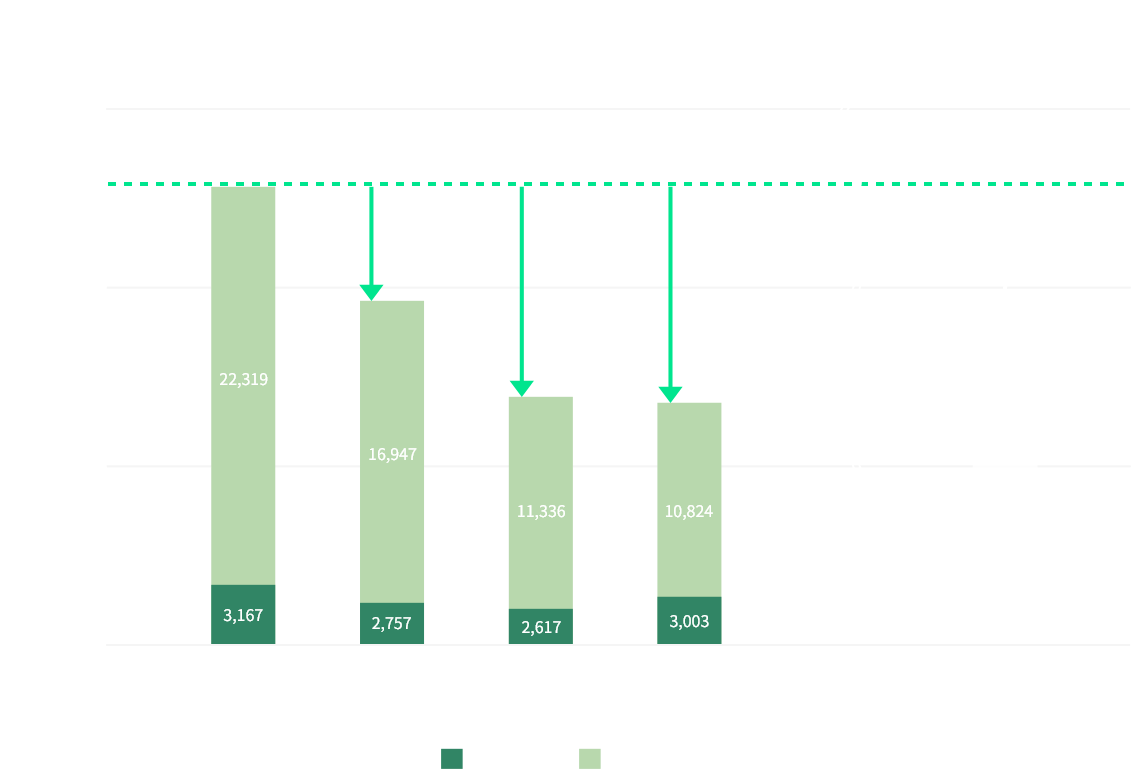

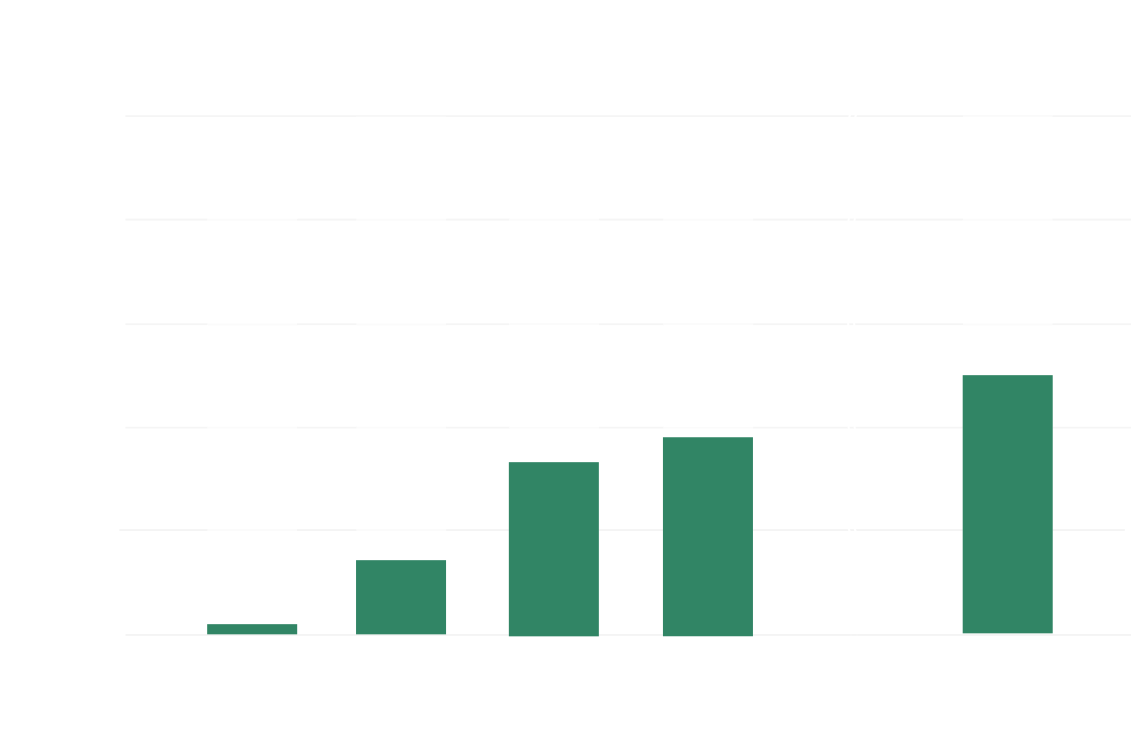

CO2 emissions

- -46%

-

Total CO2 emissions in 2024 were 13,828 tons.

Our continuing plan to transition to electricity derived from renewable energy sources has resulted in a 46% decrease in emissions, compared to 2021.

We remain committed to advancing our strategy to promote energy conservation activities and increase the ratio of renewable energy usage, along with emission reductions. -

※About "Scope"

- Scope 1: Direct greenhouse gas emissions by businesses themselves (fuel combustion, industrial processes)

- Scope 2: Indirect emissions from the use of electricity, heat, and steam supplied by other companies.

※About CO2 Emission Factors

- Electricity: In Japan, the adjusted emission factors of the electricity retailers contracted by each site are used based on the "List of Emission Factors by Electric Utility" published by the Ministry of the Environment and the Ministry of Economy, Trade and Industry of Japan.

Overseas and some sites in Japan use IEA country-specific emission factors.

The emission factor is set to zero for electricity generated through power purchase agreements (PPA). - Fuel: Emission factors by fuel published by the Ministry of the Environment and the Ministry of Economy, Trade and Industry are used for both Japan and overseas.

- Annual CO2 emissions

We have undergone third-party verification of its CO2 emissions data in order to improve data reliability.

The CO2 emissions data (Scope 1 and 2) for 2024 was found to have no deficiencies, and a greenhouse gas emissions verification report was obtained.

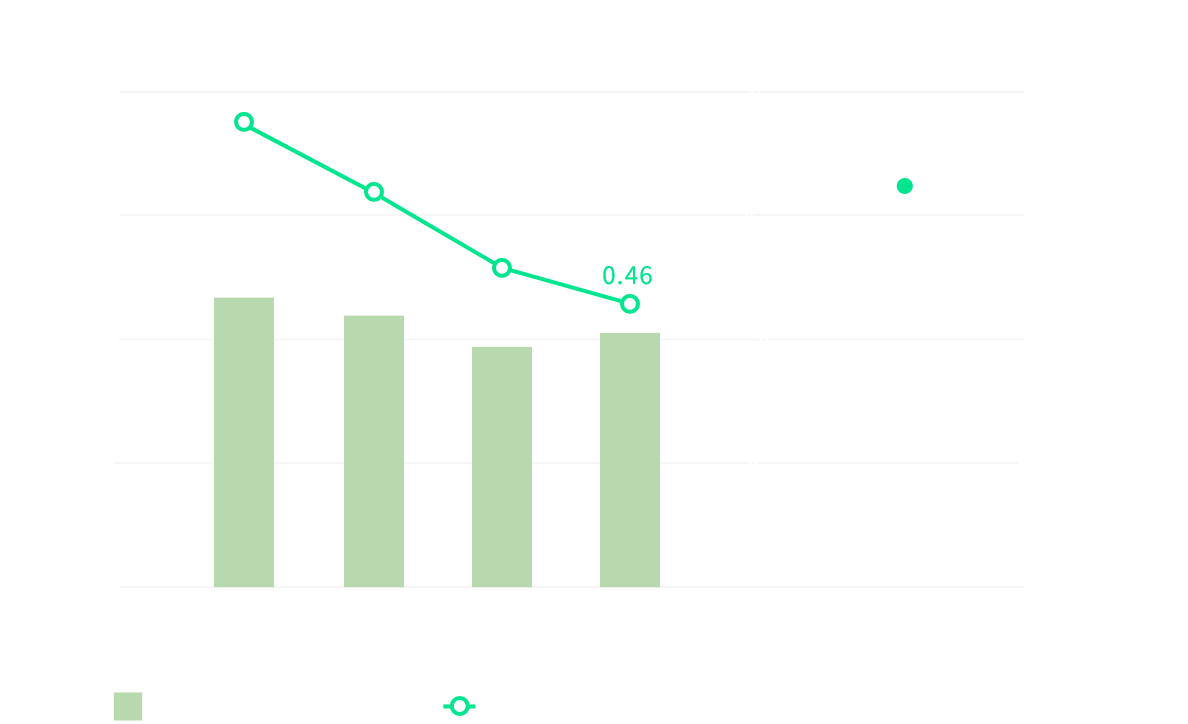

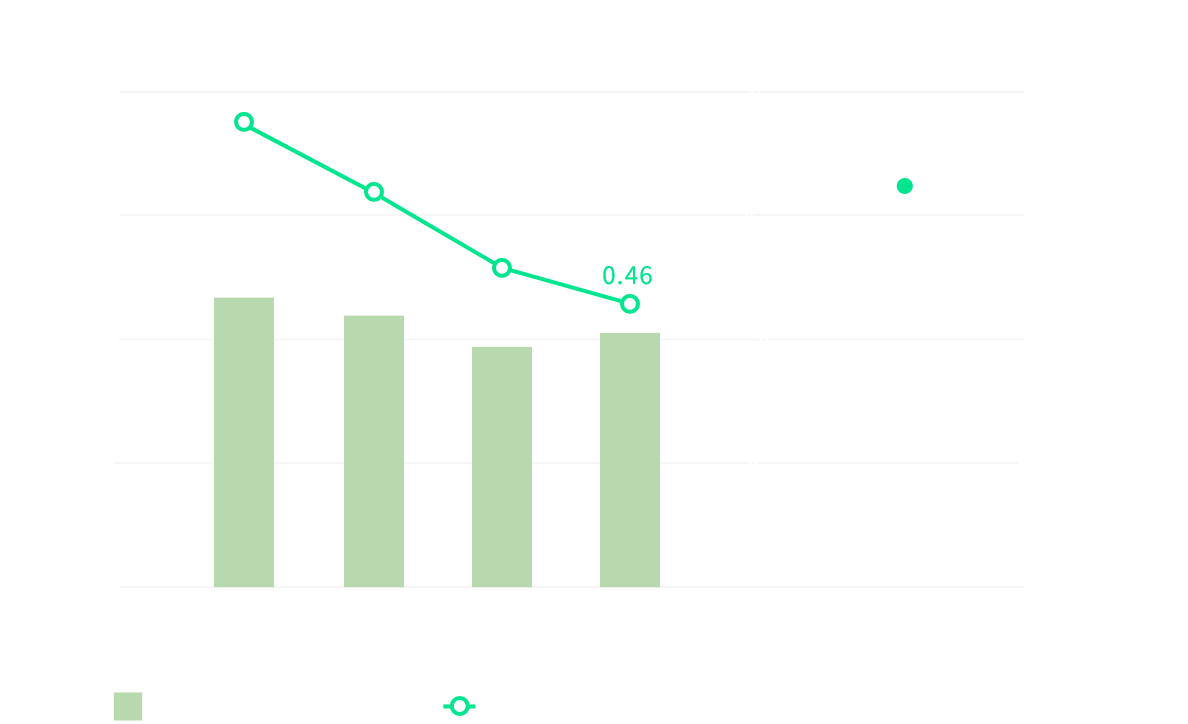

Energy

- -40%

-

Energy consumption in 2024 was 405 TJ.

Basic unit per net sales was down by 40% compared to 2021, partly due to the effect of increased sales.

We will continue to promote reduction of energy consumption through energy-conservation activities. - Energy Use Trends

-

Energy use breakdown(2024)

| 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|

| Electricity (MWh) | 42,600 | 40,521 | 39,158 | 41,855 |

| Heavy oil A (kL) | 362 | 266 | 152 | 146 |

| LPG (tons) | 360 | 380 | 351 | 366 |

| City gas (thousand Nm3) | 4 | 4 | 3 | 4 |

| Kerosene (kL) | 35 | 24 | 3 | 11 |

| Diesel (kL) | 280 | 217 | 202 | 257 |

| Gasoline (kL) | 124 | 114 | 244 | 327 |

- 2021

- 2022

- 2023

- 2024

- Electricity (MWh)

- 42,600

- 40,521

- 39,158

- 41,855

- Heavy oil A (kL)

- 362

- 266

- 152

- 146

- LPG (tons)

- 360

- 380

- 351

- 366

- City gas (thousand Nm3)

- 4

- 4

- 3

- 4

- 灯油 (kL)

- 35

- 24

- 3

- 11

- Kerosene (kL)

- 280

- 217

- 202

- 257

- Gasoline (kL)

- 124

- 114

- 244

- 327

Renewable energy

- 39%

- We have been gradually transitioning to electricity derived from renewable energy sources.

Additionally, in October of 2022, we installed solar panels with a power generation capacity of appromitely 430kW on the roof of the Gunma Plant.

Through such efforts, we have replaced 18,437MWh of electricity with electricity generated from renewable energy sources in 2024, resulting in a reduction of CO2 emissions by 8,063 tons.

The ratio of renewable energy to total energy used is 39% - Annual renewable energy adoption rate

Resources

As a result of intense business activities based on resource consumption through the course of time, we

have witnessed the depletion of resources which poses significant

challenges to the global

society.

One of such resources is plastic, which is an important material necessary for the high performance and

quality of our writing instruments and is recyclable.

We help realize a resource-circulating society by promoting resource conservation, recycling and waste

reduction.

Reducing the use of virgin plastic

Use of recycled plastic

Recycled plastic accounted for about 28% of the raw plastic materials we purchased for manufacturing products in 2024. We will continue to increase the use of recycled plastic.

Green-net Products

Green-net, our ecology brand, offers a lineup of products compliant with the Act on Promoting Green Procurement*1 and Eco Mark certification.*2

- *1 : Products using recycled plastic for at least 40% of their total plastic weight

- *2 : Products that use recycled plastic for at least 70% of the product weight

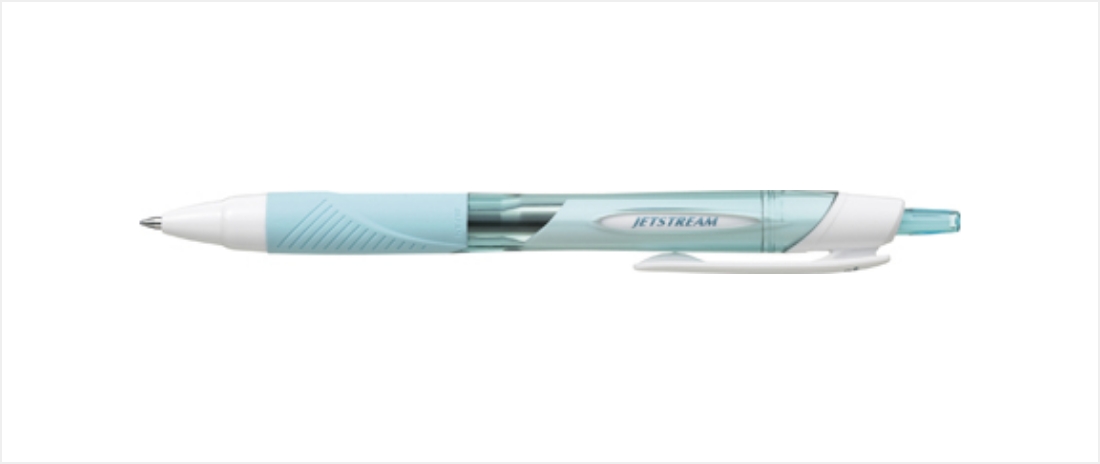

The mainstay Jetstream (SXN-150) is a Green Net product, as recycled plastics account are nearly

45% of its plastics by weight.

We provide other Green Net products as well.

Ballpoint pen made from ocean plastic waste

Jetstream Ocean Plastics was released in July 2022. They are made from plastics recycled from ocean

plastic waste collected in Japan and used disposable contact lens cases.

This product is the first product in the stationery industry to have obtained Eco Mark certification

in Eco Mark Product Category No. 164: Products made from recycled ocean plastic waste.

It was selected as a Best Product in the Eco Mark Award 2022 organized by the Eco Mark Office of the

Japan Environment Association.

A ballpoint pen made from used plastic folders

In December 2022, ASKUL Corporation released the Jetstream Ballpoint Pen Made from Plastic Folders. It uses plastics recycled from used plastic folders collected in Japan by the ASKUL Resource Recycling Platform project.

Reducing plastic usage

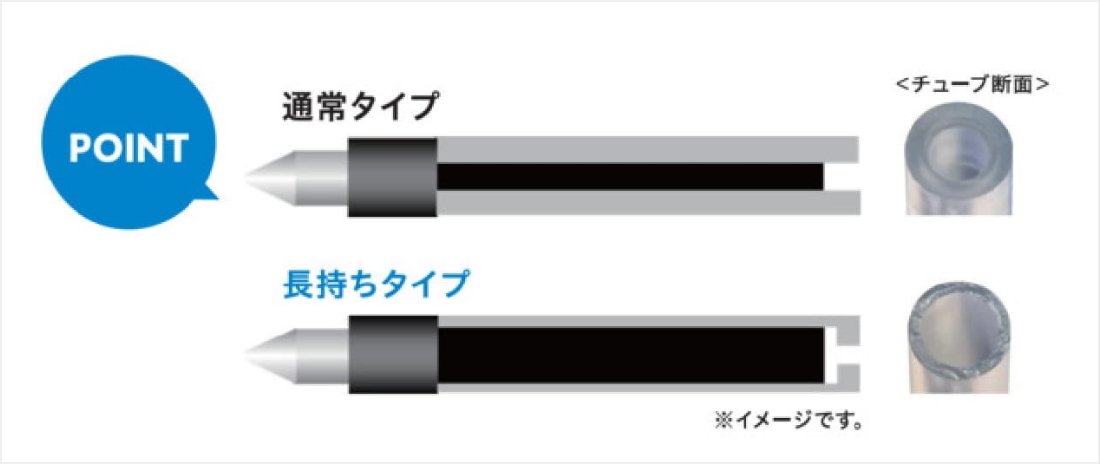

Long-lasting Refills: with 70% more ink than standard refills

For “long-lasting refills” (black ink) we launched in December 2021, we have successfully increased

the ink volume by 70% compared to our standard product (SXR-80) by making the refill tube thinner,

while keeping the same shape and compatibility with the standard product.

Additionally, we have reduced the use of plastic by about 30% compared to our standard product,

achieving an environmentally friendly design.

Development of long-lasting products

Development of long-lasting products

Even though ballpoint pens may run out of ink, the pens can still retain a longer product life by

replacing refills instead of throwing them away. This can significantly reduce plastic waste disposal.

Long-lasting products account for 48% of the unit sales of our writing materials.

Due to an increase in sales of non-long-lasting products, this percentage has decreased slightly compared to last year.

We continue to promote the development and sales of our long-lasting products.

- *Pencils and colored pencils are not included.

- *Long-lasting products include refillable ballpoint pens, refillable felt-tip pens, and refillable mechanical pencils.

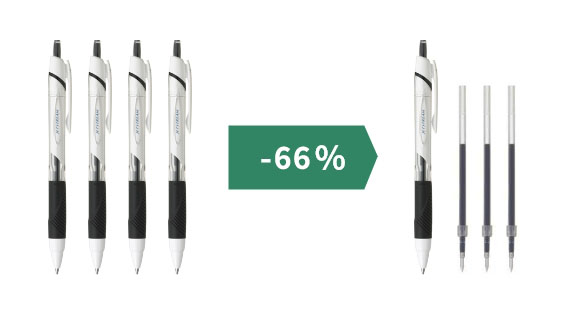

- Case for Jetstream Standard (SXN-150)

- The amount of plastic waste can be reduced by 66% by using one new Jetstream pen (SXN-150) with

three refills compared to using four new Jetstream pens.

By changing refills, a product life gets longer, reducing plastic use by 66%.

Reducing plastic use in packaging

Plastics have been used in many writing instrument packages. We are also replacing the plastics used

in packaging with paper and taking other measures to reduce plastics consumption.

Paper packaging is used for the following products: "Long-lasting refills" (upper left photo) released in November 2021, "Jetstream Multicolor Multifunction Refills" (upper right photo) renewed in November 2022, "Sharpie Refill uni Refill" (lower left photo) released in February 2023, "Sharpie Refill uni Refill S" (lower middle photo) released in May 2024, "Sharpie Refill S" (lower left photo) released in May 2024, "Sharpie Refill S" (upper right photo) renewed in November 2023. (middle of the bottom row in the photo), which will be released in May 2024, are packaged in paper packages.

We are also in the process of switching to paper packaging for products sold overseas (bottom right photo).

Reducing wastes

Total emissions (waste + valuable resources) in 2024 were about 2,200 tons. Waste plastics (35%), paper (15%) and sawdust (8%). We are reducing the amount of waste plastic through internal recycling, promoting thorough sorting, and increasing the material recycling rate*1. The material recycling rate for waste plastics increased from 9% in 2021 to 30% in 2024. Most of the paper is recycled as material. Most of the sawdust generated during the production of pencils is effectively used as compost material. The recycling rate (including thermal recovery*2) is approximately 94%.

- *1. Material recycling is the reuse of waste as a raw material for products after being crushed, melted and otherwise processed.

- *2. Thermal recovery is the recovery of energy by incinerating waste to use it for power generation and other purposes.

- The scope of emission data covers the following domestic sites.

- MITSUBISHI PENCIL COMPANY, LIMITED (Head Office, Gunma Plant, Yokohama Office, Yamagata Plant)

- Yamagata Mitsubishi Pencil Precision Co., Ltd., Uni Polymer Co., Ltd. (Gunma Plant and Yamagata Plant) and Uni Co., Ltd.

Collecting and recycling used products

Horizontal recycling

We are working on the "Pen to Pen Horizontal Recycling" project, which involves making new pens

from used* plastic pens. Through this project, we are manufacturing pens using collected

used plastic pens as raw materials and working on reducing CO2 emissions through this process.

*This project is part of the Ministry of the Environment's “FY2022 Demonstration Project for a Plastic Resource Circulation System toward a Decarbonized Society".

*The project will primarily collect "used pens" that are no longer suitable for replacing refills or are no longer in use.

Environmental pollution

We are striving to control chemical emissions and to reduce water intake to prevent health hazards that

arise due to the chemicals used in products and manufacturing processes and to conserve water resources.

Controlling chemicals emissions

We have established a Chemicals Committee. It is dedicated to creating a database of information on

chemicals used in products and manufacturing processes and to managing it properly. In so doing, we comply

with laws and regulations concerning chemicals without fail.

We also monitor and manage the status of use of the chemicals in production at individual factories and

regularly report on the substances subject to the Pollutant Release and Transfer Register (PRTR)

system.

We are also working to reduce emissions of volatile organic compounds (VOCs).

Additionally, we properly implement wastewater quality management in accordance with laws, ordinances and

local regulations.

Reducing water withdrawals

Water withdrawals in 2024 was approximately 220 thousand ㎥.

This is approximately 22% less than in 2021, the year with the highest water withdrawals in recent years.

The head office building is equipped with a system that uses rainwater as wastewater for toilets, etc. In 2024, approximately 11% (800 ㎥) of the water withdrawals at the head office building will be covered by rainwater.

We will continue to promote reductions in water consumption by improving production processes and increasing the efficiency of water use.

- ※Regarding water withdrawals, the scope of coverage has been changed to include all domestic and overseas sites of our group.

Biodiversity

Deforestation due to illegal logging, etc., is rapidly increasing, causing adverse effects on ecosystems

including flora and fauna as well as

frequent disasters in recent years such as floods and

landslides due to torrential rains, which poses significant challenges to the

international society.

We are addressing the problem by using certified wood for our pencils in order to help protect biodiversity

and ecosystems.

Obtaining forest certification for the wood used in pencils.

For the wood used in our pencil products, we have adopted 100% certified forest wood (such as PEFC) from 2024 onward.

In addition, for the processing and distribution process, our Hi-uni product obtained PEFC certification in December 2022 (PEFC ST 2002:2020).

We will continue to procure certified wood and expand the scope of certification for processing and distribution processes.

- *PEFC (Program for the Endorsement of Forest Certification)

- Supplementary information

- Covered period :

Unless otherwise specified, the information provided here is for January-December 2024. Historical data for the past few years and information for 2025 are also included as necessary.

Scope of Coverage :

Unless otherwise specified, this covers all domestic and overseas sites of our group.

In April 2024, we made C. Josef Lamy GmbH a consolidated subsidiary.

However, since the aggregation of environmental information has not been completed, it is not included in our group's overall calculation results for 2024.

Update: August 21, 2025