Features of Carbon Manufacturing Technology / PFC

Mitsubishi Pencil has a longstanding tradition of integrating carbon materials into its writing instruments. Our Plastic Formed Carbon (PFC) product line applies this expertise to a wide

range of applications. PFC boasts high purity and mechanical stiffness, along with key characteristics of carbon materials such as electrical conductivity, thermal stability, corrosion

resistance, and biocompatibility. These properties make it suitable for various industries and diverse applications.

Carbon products

Plastic Formed Carbon Manufacturing Technology

Carbon products leverage the exceptional properties of their base material: lightweight and stiff, making it ideal for diaphragms and ultrasonic matching layers. Its hardness and tribological

features make it perfect for sliding elements. By controlling pore size, we can fine-tune the material's characteristics for optimal porosity. With excellent corrosion resistance and electrical conductivity, PFC is the material of choice for electrodes.

-

Carbon Matching Layer

Matching layers are widely used in ultrasonic probes, and our product allows for fine tuning of the acoustic characteristics.

-

Carbon Diaphragm

Carbon diaphragms are used in high fidelity tweeters, for high frequency pitched acoustic speakers.

-

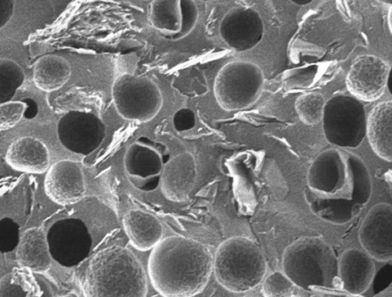

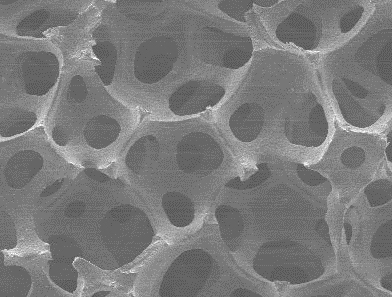

Carbon Porous and Dense materials

Controlling the pore size during production while taking advantage of chemical and thermal resistance is key for manufacturing customizable porous and dense materials.

-

Carbon Electrode

An impermeable and chemically resistant carbon material is ideal for measuring the electrical characteristics of fluids.