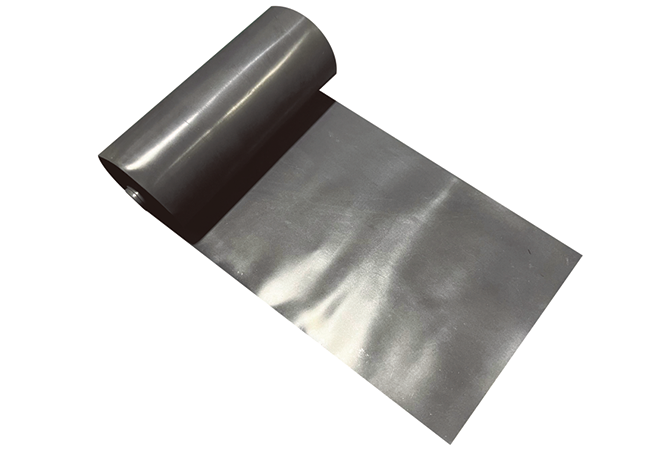

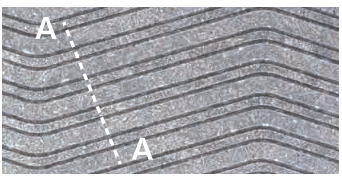

PTFE dispersion

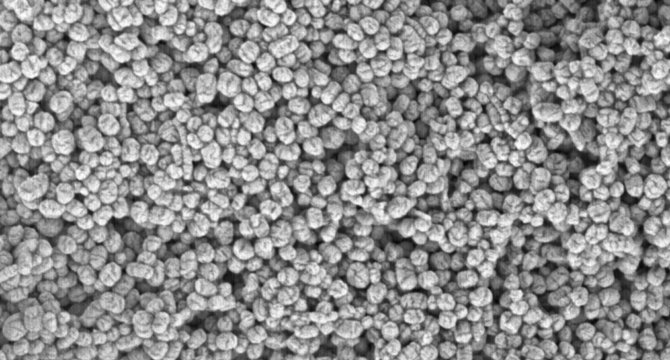

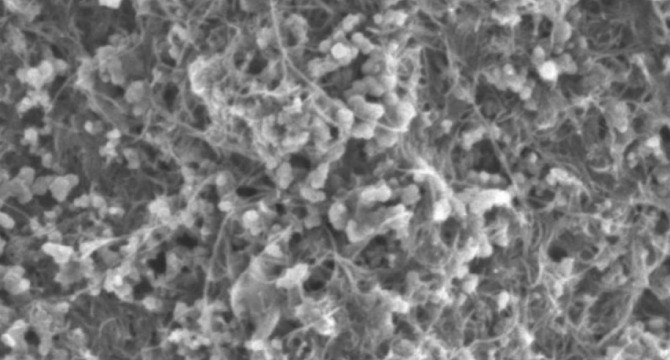

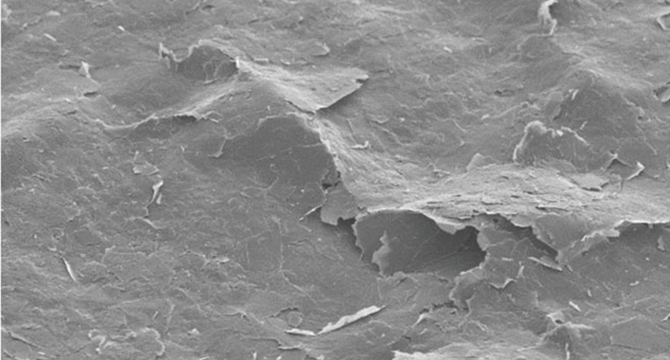

Through developing advanced inks, we mastered ultrafine particle dispersion technology. Our PTFE dispersion applies this expertise to distribute fine PTFE particles, unlocking the benefits of this high-performance engineering plastic. Empower your products/processes with the unique properties of PTFE using our innovative dispersion solution.